Converter Solutions

-

What is a converter?

-

Converters enhance the value of 3M's top-tier tape adhesive technologies by crafting customized, cost-efficient shaped components tailored to your specific requirements. Their expertise encompasses materials and adhesive knowledge, complementing your design insights with practical adhesive solutions. Beyond adhesive recommendations, 3M converter partners bring extensive engineering know-how to the table, actively aiding your design process.

Connect with 3M experts

If you are interested in learning more about our effective converting solutions and how they can be used to add value to your manufacturing process, click below.

-

Kiss cutting

What Is Kiss Cutting and Why Does It Matter?

If you're in production you've probably come across the term kiss cutting. But do you really know how it works? Kiss cutting is a specialized cutting technique that cuts through the top layer of a material while leaving the backing intact. Kiss cutting is the solution that enhances design flexibility, and application ease. Whether you're in manufacturing or design understanding kiss cutting can help you make better production choices.

-

-

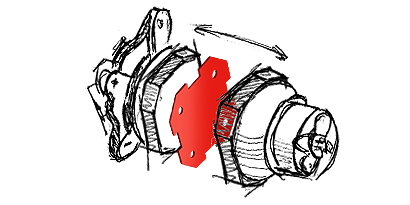

Die cutting

Tape die cutting is the process of using custom dies to cut adhesive materials into precise shapes for industrial and commercial applications. This allows manufacturers to create highly functional components with speed and consistency.

In today’s fast-paced industries, precision and efficiency are non-negotiable. Tape die cutting has emerged as a transformative solution for custom shapes and sizes, improving performance in various sectors.

-

-

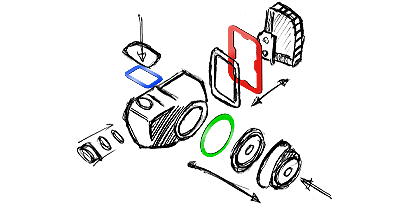

Laser cutting

As the industry evolves, the demand for lightweight, durable, and high-performance materials is greater than ever. Laser cutting is playing a key role in this transformation, enabling precise fabrication of adhesive-backed parts used for sealing, bonding, and noise reduction.

From foam double-stick tape for cushioning to pressure-sensitive adhesive tape for trim attachment and acoustic damping materials for reducing cabin noise, laser-cut adhesives provide superior accuracy, efficiency, and design flexibility.

-

-

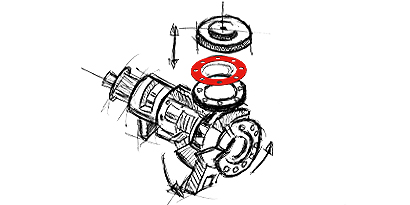

Slitting

Precision Slitting. The ability to tailor adhesive materials for sealing, bonding, insulation, and noise reduction is crucial for efficiency and durability. Slitting technology enables manufacturers to custom-cut adhesive tapes, foams, and films to exact widths, ensuring seamless integration into industrial machinery.

-

Applications

-

Automotive

Maximize the efficiency of automotive manufacturing, whether you’re an OEM or Tier supplier. 3M tapes and adhesives are designed to help you achieve your production goals quickly and cost-effectively. From interior trim mounting to exteriors that are exposed to the elements, we’ll work with you to understand your challenges and help find solutions.

-

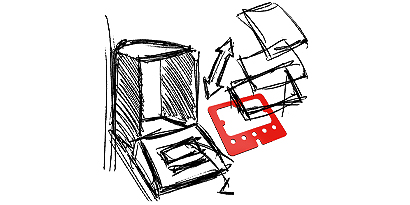

Appliance

If you’re a design engineer, a 3M converter partner can help improve the appearance, manufacturing process and performance of your appliances with custom die cut adhesive bonding tape solutions plus application expertise to help take your ideas from concept to production faster.

-

General Industry

Rubber, silicone, metals, gaskets, die cuts-virtually any substrate, material, application or shape can be achieved with the help of a 3M converter partner.

-

Electronics

Electronics manufacturing is constantly changing, and electronics designers need solutions that help bring their ideas to life. From drop-resistant and waterproof bonding to mounting flexible screens, 3M tapes and adhesives are engineered to meet challenges head on.

Solving Design Challenges

-

Materials Expertise & Consulting

You know design. We know adhesives. Converters know both. This means you can get the adhesive solution you need to turn your ideas into reality quickly.

-

Customized Converted Formats

3M converter partners are experts in helping you think outside the box and apply solutions that take a variety of formats and offer benefits beyond what you might expect.

-

Prototyping Capabilities

3M converter can work with you to create customized adhesive prototypes that you can test with your design.

-

What converters work with

Tapes, labels, release liners: whatever you need, our converter partners can put it together and provide it in the format you require.

The brands listed above are trademarks of 3M.